Heraclitus’ Greek aphorism, according to which everything flows, takes on additional significance in the field of materials science. The principle of eternal becoming and change can be translated here as meaning that nothing is truly fixed and, contrary to expectations, some things are not really sharply separated. This is a unique perspective on the structure of materials and their relationships, on the interplay between substances and things. And what all this has to do with the production of modern microchips, which are found in our smartphones and smartwatches, will be discussed on the following pages.

At first, it makes sense to introduce the subject itself: Materials science is a discipline that lies between chemistry, physics, and engineering, linking these fields in a unique perspective. It is therefore an interdisciplinary field that deals with the research, development, and application of materials. As a science that focuses on materials, it aims to understand mixtures of substances, their interactions, and the resulting properties. It deals with chemical descriptions as well as physical, chemical, and mechanical characterizations, analyses of the structures and composition of substances, and the manufacturing conditions described by factors of thermodynamics and kinetics. The focus is therefore on thermodynamic and kinetic fundamentals for materials that are important in engineering: approaches are developed through the creation of phase diagrams, the investigation of diffusion processes, and the characterization of internal interfaces.

Furthermore, one subfield of materials science deals with the development of new or adapted materials with specific properties that are tailored to the requirements of certain applications. When we think of the highly specialized materials used in modern microelectronics, for example, which form the basis for miniaturization and increased performance, it becomes clear how materials science taps into innovative potential through its combination of natural science and engineering approaches. This also demonstrates the bridge between basic research and its transfer into application-oriented reality, which is particularly important as a productive link between research and development for universities of applied sciences.

How do materials scientists work?

Phase diagrams, i.e., representations of phase transitions as a function of various parameters, are useful for understanding the properties of substances and how they change in different states. In these diagrams, phase transitions (from solid to liquid to gas, etc.) are represented by influencing factors such as composition and temperature. The substances or individual components have different relevant properties depending on their state and, among other things, during the transitions, which need to be characterized. These diagrams can be used to investigate thermodynamic and kinetic behavior, which can then be used specifically in manufacturing processes, for example.

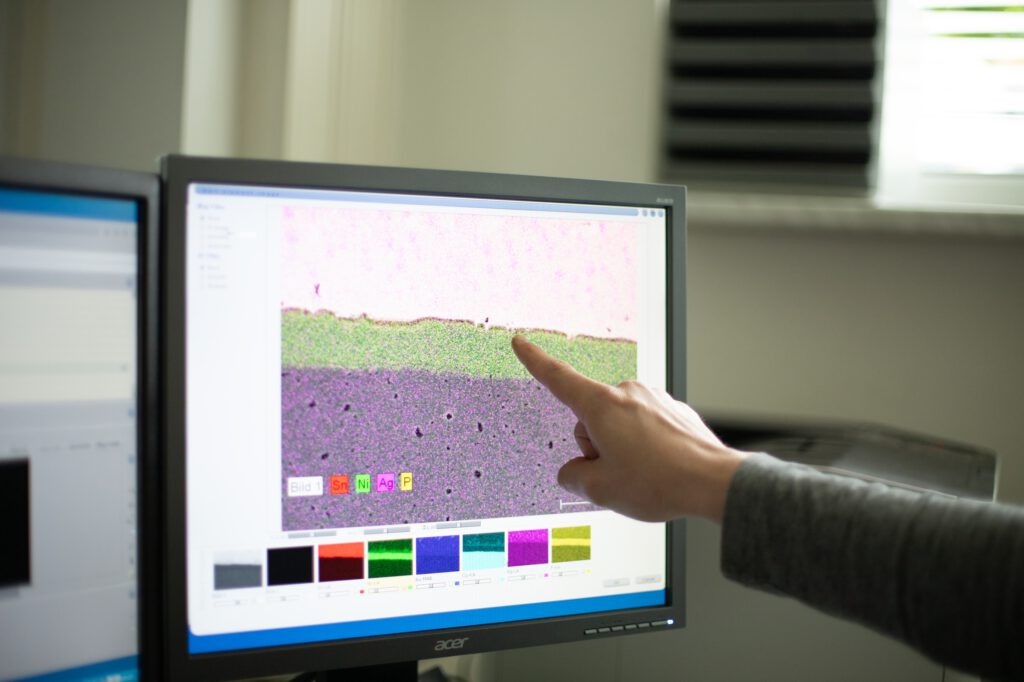

Another aspect within materials science is diffusion, i.e., the interactions between substances, for example, between two metal layers. Our everyday understanding suggests that there are no interactions between the two metals, as both are solid bodies that exist completely separately. However, if we use low-scale observation methods such as electron microscopes, in which the atoms and atomic lattices become visible, the picture changes: to stay with our example, relationships can exist between the metals, which can lead, among other things, to mutual mixing or even to the incorporation of one substance by the other. When different metals and alloys are combined, as in microchip manufacturing in electrical engineering, such effects must be taken into account, which is the focus of materials science.

The investigation of such interdiffusion processes is one aspect of materials science that leads us to Martin Seyring and his research at Schmalkalden University of Applied Sciences. Dr. Martin Seyring joined HSM in October 2022 as a research assistant for scanning electron and optical microscopy at the Faculty of Electrical Engineering. Previously, he researched and taught at Friedrich Schiller University in Jena, where he also earned his doctorate.

Materials science research at HSM

Martin Seyring’s research focuses on phase imbalances at metallic interfaces, which in the field of materials science encompasses processes such as interdiffusion. At HSM, he works with Roy Knechtel, who holds the professorship for Autonomous Intelligent Systems. Both are now conducting research into the development of microelectronic components, known as MEMS. Among other things, this involves pressure, acceleration, rotation rate, infrared radiation, and tilt sensors, which form the technological basis of our modern devices such as smartphones and smartwatches. While Roy Knechtel focuses on the microelectronic design and integration of the sensors, Martin Seyring is dedicated to the integration of the sensors, which is achieved through processes such as bonding and soldering, for example, thus contributing his experience in the metallurgical field of materials science. In order to advance the goal of achieving ever higher integration densities and realizing smaller, more efficient, and more powerful components, the related materials and their complex relationships are increasingly coming into focus.

One goal is to maximize the technical potential when connecting the tiny structures on and with the silicon wafer. Of course, there is not just one bonding process, but various methods that are suitable for different applications. In addition to anodic bonding and, for example, glass frit bonding, metals or alloys can also be used for bonding in metallic bonding, and this is where Martin Seyring’s research and his experience with metallic materials and the behavior of thin films come into play. What are the relationships between the individual metal layers—some of which are created during bonding, soldering, and coating—and how can these be optimized in various ways?

An important aspect of the interactions is time: diffusion and chemical reactions sometimes proceed very slowly, but their consequences are significant. Naturally, temperature is a factor that accelerates both of these processes. This also presents an opportunity for research: by controlled increases in temperature, a longer period of time can be simulated and the effects on the materials studied. This makes it possible to answer questions such as how hot components can become or how thin the related layers can be, which is particularly relevant from the perspective of efficient high-volume production.

Where technology and ecology meet

Sustainability is an important aspect that leads us neatly to a current research project by Martin Seyring and Roy Knechtel. The title of the project is MatInWLP, which stands for material innovations in wafer-level packaging. Once again, the topics we have discussed so far come together in a new context. In addition to the focus on materials, WLP is at the center of attention: This refers to the attempt to apply the components directly to the wafer, thereby eliminating many individual process steps. In other words, with WLP, the steps involved in building semiconductor chips into usable components take place simultaneously and directly at the wafer level, including the steps of encapsulation and contacting. This project also addresses innovative 3D printing technologies that could play a role in WLP.

To understand the innovative nature of this technology, it is important to consider the current state of chip production: despite or regardless of the enormous increase in the quantity – as well as the quality – of microelectronic components produced, their manufacture still involves an immense logistical effort. The components travel around the globe for the many individual manufacturing steps, leaving a significant ecological footprint. Furthermore, the sometimes sensitive origins of related materials such as cobalt must be taken into account: the trend toward ever greater miniaturization is offset in terms of material consumption by the sheer mass of chips produced. The MatInWLP project combines technological and ecological ambitions: on the one hand, it involves the technical realization of direct integration of the components on the wafer, which is challenging enough in itself. On the other hand, it involves an attempt to minimize not only transport costs but also material usage through direct bundling on the wafer, thereby further reducing the ecological follow-up costs.

The MatInWLP research project is funded by the Carl Zeiss Foundation, which recognizes the technological, economic, and ecological potential of optimizing manufacturing processes and material combinations. Added to this are the advantages of applied sciences, such as their practical orientation, which places particular emphasis on the implementation of the knowledge gained. The project will run until early 2027 and has been awarded €1,000,000 in funding.