Toolmaking covers a wide and diverse range, including tool development, manufacturing, and use. The design and manufacture of precise and complex tools with high performance and durability is a cornerstone of modern industry, and the current crises are affecting both mechanical engineering in general and toolmaking in particular.

Starting with the design of special cutting tools (e.g., milling tools or drills) and the application of coatings, toolmaking also deals with customized production processes and the reconditioning of tools. Without being the center of attention itself, toolmaking plays a relevant role in improving people’s everyday lives, whether through the manufacture of household appliances, the expansion of the technical infrastructure of our mobility (in addition to automobiles, trains, among other things), or the development of forward-looking technologies in microelectronics and space travel.

The Schmalkalden Tool Conference, organized by the GFE (Gesellschaft für Fertigungstechnik und Entwicklung Schmalkalden e.V.) in cooperation with the Schmalkalden University of Applied Sciences and the VDMA (German Engineering Federation). Renowned companies and research institutions not only provided insights into approaches to technological development and experiences in their application, but also focused on how to deal with these challenging times.

The motto of this year’s biennial conference was “Resource-efficient & economical tool development, manufacturing, and use,” focusing on the productive combination of ecological sustainability, technological efficiency, and economic optimization. Despite their different emphases, all three aspects can be positively combined and motivate each other, thus helping toolmakers to find robust answers to the questions and tasks of the present.

External influences: International raw material markets and bureaucracies

One current challenge facing tool manufacturers is the availability of raw materials such as tungsten, which form the basis of carbide tools. Their distribution on the European market is currently very limited, and prices have skyrocketed in some cases over the last six months: Not only has China restricted exports of these metals, it is also buying up the remaining raw materials on the global markets on a massive scale. This has resulted in shortages and increased costs. This trend is even evident in scrap metal, which is also being skimmed off the European market by higher price offers from China via . One response from the industry is to secure its own sources of raw materials, to pursue recycling even more vigorously, and to keep scrap metal as a valuable raw material on the European market, because the short-term losses in sales price are justified by medium and long-term advantages. At the same time, the goal must be to use scarce resources efficiently, which in turn gives momentum to approaches for recycling tools and their sustainable, optimal use, as was also made clear at the tool conference.

Like many other industries, toolmaking is also burdened by bureaucratic obstacles, which is a second external factor. In addition to the national level, there is also the transnational level of the European Union, which, in the concrete experience of toolmaking, leads to a confusing jumble of different actors and legal regulations that is almost impossible to navigate. For example, the import of raw materials often involves complex tasks with different documentation requirements. Another issue is the decreasing time horizon for policy decisions: industrial transformation processes require long-term perspectives and the certainty that investments will pay off. The policy framework therefore lacks a regulatory orientation, which in turn is central to setting innovative impulses.

One response to restrictive regulations is research and development: if the EU bans the use of lead in materials such as aluminum, then an adequate substitute must be found. First, the effect of lead as a component and in processing had to be understood: in short, lead has a positive influence as a plasticizer and lubricant in processing, particularly with regard to the ideal of producing many small chips during milling. If it is removed from the material, the result is reduced chip breakage during machining processes, which in turn leads to long, tangled chips that clog the machine, stop the production process, and are difficult to remove. One way forward would be to adapt the tools, for example by changing their geometry, in order to promote chip breakage and make the use of lead-reduced alloys such as brass feasible. This could therefore be an alternative that meets production standards, although the parameters of usability and scalability on an industrial production scale still need to be examined.

The elective affinity of efficiency and ecology

Another answer is to further optimize tool manufacturing processes, which has always been a motive for tool production. There are various approaches to this: one possibility presented at the conference is simulation-based milling tool development. This optimization guarantees the quality of production and minimizes tool wear at the same time. Such an approach uses so-called gray box models to predict tool wear and maximize tool life. An abstract physical model (white box) is combined with a model trained on real sensor data (black box) to estimate the ideal point of wear. Efficient use of the tools minimizes the amount of material and energy required.

Another option is to build tools in a modular fashion so that, when wear and tear occurs, only those parts that have actually become unusable need to be replaced. As with many applications, the implementation of sustainability principles must be considered as early as the tool design stage. Which parts are most likely to need replacement, where can a tool be sensibly divided, etc.? Ideally, sustainable tool use would be based on the principles of “recycle, reduce, reuse,” which was also the title of a presentation at the tool conference.

Last but not least, artificial intelligence was, as expected, a topic that is driving the industry. It is important to note that this is neither a buzzword nor a promise of salvation, but rather a tool that, when used in the right place and in the right way, can offer advantages, including in the evaluation of data and the subsequent optimization of manufacturing processes. Just as in the case of additive manufacturing, experience in dealing with this technology is needed to determine its advantages and disadvantages in concrete terms. Here, the industry is still searching for the ideal fit for AI-supported technologies.

Space and the vacuum. Innovation and outlook

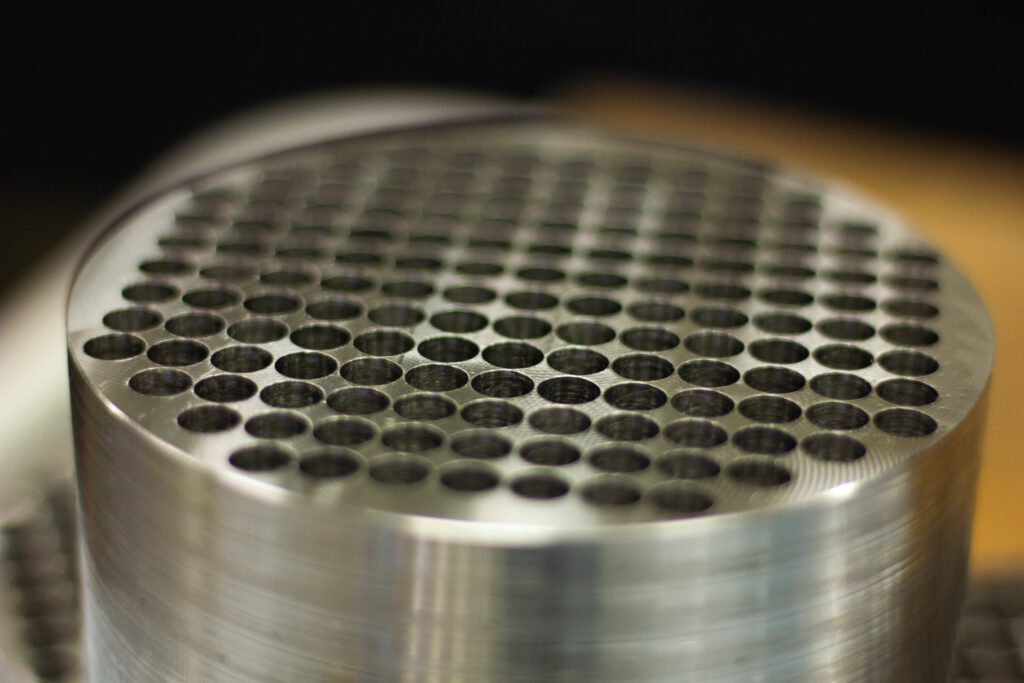

Two presentations provided impetus with regard to specific fields of application: Spaceoptix, a company based in Jena and spun off from Fraunhofer IOF, is involved in the development, manufacture, and integration of high-precision metal optics and mirror systems, which are used in satellite communications, among other things. These areas of application place high demands on manufacturing processes (CNC milling, turning, and polishing, among others) and the tools used. One specific research project in which Spaceoptix is involved is satellite-assisted monitoring of the water supply for agricultural land.

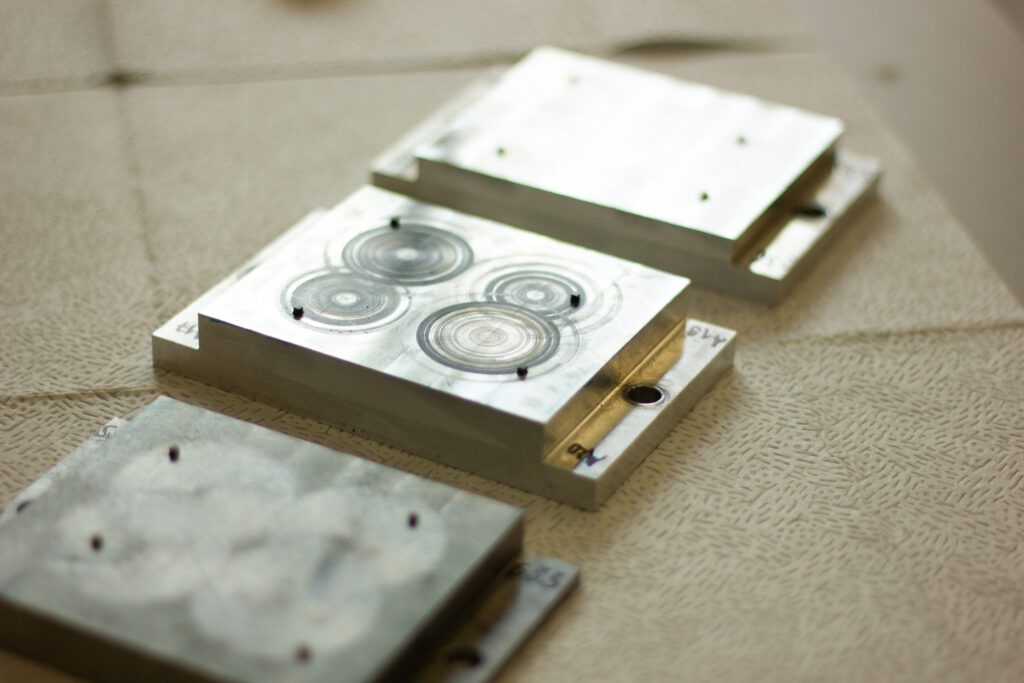

The second impetus came from VACOM, a company that has found a unique selling point in vacuum technology for applications in research and industry and works for partners in aerospace technology and coating processes, among other areas. The manufacture of high-purity components and the cleaning of components is a growing field that is currently being exploited by cutting-edge technologies: For example, the manufacture of state-of-the-art computer chips using EUV lithography – the abbreviation stands for extreme ultraviolet light – requires not only the highest quality components, but also a high degree of surface cleanliness for all components. The manufacture and subsequent cleaning of components for the semiconductor industry, in turn, sets high standards for manufacturing processes.

Cutting-edge technology requires skilled professionals who are well-versed in research and application: in addition to companies such as VACOM, which are firmly committed to training, the development of young talent is also a task for universities. Tomorrow’s skilled workers are trained at universities of applied sciences such as the University of Applied Sciences Schmalkalden, where the focus is not only on theoretical knowledge but also on teaching practical skills. This is also evident in the tandem professorship of Andreas Wirtz, who works equally at GFE and HSM: As head of the “Cutting Tools & Technology” division at GFE’s and holder of the professorship for “Manufacturing Technology and Virtual Process Design” at HSM, Professor Wirtz can combine the experience of both worlds to the benefit of his research and teaching. In addition to the tool conference, it is Andreas Wirtz’s tandem professorship that demonstrates the possibilities for trusting cooperation between science and industry.